Our Know-How

All viticulture, winemaking and ageing work is carried out on the domaine Veuve

Maurice Lepitre. The numerous cares brought to our vines and our wines reflect all

the best this incredible terroir has to offer!

Harvest

In Champagne, the analysis of the maturity of the grapes by “Cru” makes it possible to determine the precise date of the beginning of the grape harvest.

The basic yield, the quantity of grapes to be picked per hectare each year, is set by decree.

Hand-picking of whole bunches of grapes is compulsory and we sort the grapes by plot to eliminate spoiled grapes.

Learn more

Maturity analysis

Every week, as the grapes begin to change colour (“veraison”), samples are taken from several plots for analysis.

The maturity of the grapes, defined mainly by the sugar and acidity levels, are decisive in choosing a date for harvesting in our village, which takes place every year in August or September.

Yield regulation

The basic yield of the harvest is regulated by the INAO (the organisation responsible for regulating French agricultural products with Protected Designation of Origin) which can be revised upwards or downwards depending on the quality and quantity of the AOC Champagne grapes.

Grapes are picked by hand

In Champagne, the harvest is picked manually in order to not damage the berries which must arrive intact at the pressing. The pickers therefore pick whole bunches of grapes so that they avoid tinting the juice with its skin.

Sorting by plot

More than 100,000 pickers work in teams of 4 or 5 per hectare. The pickers have a window of about three weeks to work because beyond this period, the grapes are at risk of rotting. They are also sorted at the time of picking.

Pressing

The freshly picked grapes are transported to our pressing centre under conditions that limit their oxidation and maceration, where they are weighed and pressed within a maximum of 18 hours.

From 4000 Kg of grapes (constituting a “marc”), we obtain 2 qualities of grape juice (“must”): the first fraction corresponds to 20.5 hectolitres of “cuvée” and the second corresponds to 5 hectolitres of “taille” each with their own organoleptic characteristics.

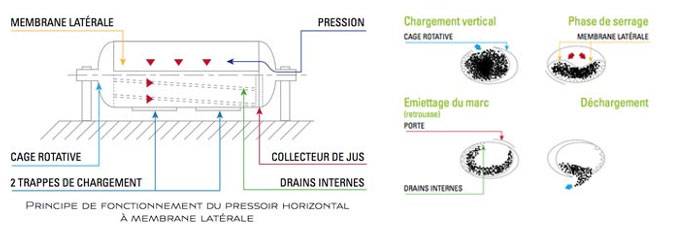

Since 1990, we have been using our own horizontal pneumatic membrane press, approved in terms of quality by the CIVC (Champagne Comitee). It guarantees us the best possible pressing quality whatever the climatic conditions of the harvest according to the strict regulations of the AOC Champagne.

As part of our “high environmental value” approach, we responsibly manage by-products and waste by sending them to the distillery. Wine effluents (water used to clean the press, grape boxes and vats) are recovered for treatment so as not to harm the environment.

Learn more

The press house

The grapes are transported to the pressing centre in crates with drainage holes to prevent oxidation and maceration. As soon as they arrive at the pressing centre, the grapes are weighed and recorded in a register. After being weighed, they are taken to the press and pressed within a maximum of 18 hours. This reactivity avoids the colouring of the juice because ¾ of Champagne wines are made from black-skinned grapes.

Moreover, it avoids the oxidation of the juice to preserve its most delicate aromas. It is the pulp which contains the organoleptic compounds and the elements necessary for effervescence and only the pulp can give the clear juice and the desired pale colour.

The fractioning

A press book is kept during pressing to identify each “marc”. Only 25.50 hectolitres of must can be extracted from a 4000 kilogram “marc”, the traditional pressing unit. Pressing is split by separating the first juice extracted, 20.50 hl which constitutes the “cuvée”, from the next 5 hl, called “taille”.

The musts have very specific analytical characteristics. The cuvée, which represents the purest juice from the pulp rich in sugar and acids (tartaric and malic), gives wines of great finesse, with subtle aromas with a good freshness in the mouth and a better aptitude for ageing.

The pruning, also rich in sugar with less acidity but more mineral salts (potassium in particular) and colouring matter, produces wines with intense aromatic characters, that are fruitier in their youth, but with less longevity.

Our wine press

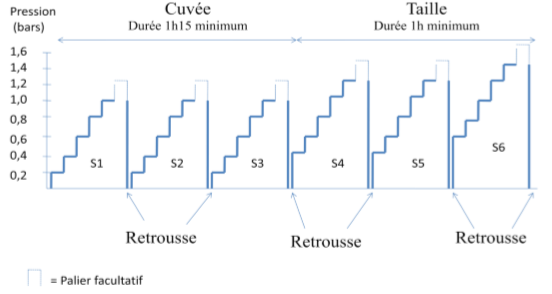

During pressing, the food grade plastic membraneinflates with air to press the grapes slowly and progressively. Its pressure increases in increments of 0.2 bars in 0.2 bars.

On the opposite side, the horizontal cage is equipped with drains to collect the juices and ensure their flow to the juice collector to the belons (open tanks).

The turning back, reworking of the puddle cake between each greenhouse, is done by deflating the membrane and rotating the cage. Unloading is automatic by opening the press doors and making continuous rotations of the cage.

Hygiene and high environmental value

Between each pomace, the press must be emptied and cleaned with water. As part of the sustainable viticulture approach, at the end of pressing, the “aignes” (solid residues from the “marcs”) must be sent to the distillery and the wine effluents are recovered for treatment so as not to harm the environment.

Winemaking

Always sparingly, we sulphite throughout the winemaking process to preserve the physico-chemical and sensory characteristics of our wines by avoiding oxidation and to facilitate the settling of the must.

The must resulting from the pressing process settles for a few hours through the settling process allowing its first clarification by eliminating its impurities.

After racking, the must will undergo alcoholic fermentation, allowing the transformation of sugars into alcohol under the action of yeasts. The wine thus obtained will be softened and gain in stability through malolactic fermentation, which will give it a brioche note. A second stage of clarification will followin order to improve the clarity of the wine as much as possible.

Learn more

Sulphiting

The juices that come out of the press are collected in vats called “belons” in Champagne. Sulphiting (addition of sulphur dioxide or SO2) takes place continuously as soon as it leaves the press, at doses varying from 6 to 10 g/hl depending on the grape variety, the health of the grapes and the fraction (size or vintage).

Because of its antiseptic power, sulphiting plays an important role in the control of undesirable Levarian and indigenous bacterial populations. Through its antioxidant power, it participates throughout the winemaking process in the preservation of the physico-chemical and sensory characteristics of the wines. It also facilitates the settling stage that follows.

Settling the must

The settling consists in a static settling of the juices. In the first few hours, a flocculation of the enzymes naturally present in the juice or added. The flocs formed settle at the bottom of the tank with the other particles suspended in the juice (fragments of skins, seeds, etc…) forming the lees. After 12 to 24 hours, the lees are separated from the must (clear juice) by racking. The lees (between 1 and 4 % of the volume) are declared and sent to the distillery.

After clarification, the racked must is sent to the winery for the first stages of vinification. This is the fermentation of these clear juices in order to obtain fruity and aromatically frank wines. The contents of each vat are clearly identified by the mention of the fractioning, the grape variety, and the year.

Alcoholic fermentation

The first fermentation of Champagne wines is the alcoholic fermentation which transforms the must into wine. The yeasts “eat” the sugar and thus produce alcohol and carbon dioxide, as well as other components (higher alcohols, esters) that build the sensory characteristics of the wine.

The must that has been settled is chaptalized if necessary, the aim is to obtain a maximum of 11 % vol. of alcohol at the end of fermentation.

Yeasting with selected yeasts (Saccharomyces cerevisiae) allows for a greater control of the fermentation process. This transformation lasts for about fifteen days and generates a strong rise in temperature, which needs to be regulated, at around 18-20°C, in order to limit the loss of aromas and the risks of stopping fermentation.

On a daily basis, the monitoring of the fermentation, thanks to the control of temperature and density, is carried out..

Malolactic fermentation

Our strategy is to carry out the malolactic fermentation on our wines at the end of the alcoholic fermentation. The transformation of malic acid into lactic acid brings aromatic notes of brioche and butter to our wines and also a certain suppleness as it reduces their acidity. This fermentation also generates other compounds that modifies the organoleptic profile of the wine.

The temperature in the vat room is maintained at around 18°C and the vats are inoculated with selected lyophilized bacteria. The evolution of the malolactic fermentation is assessed by monitoring the total acidity. It lasts between four and six weeks, after which the wines are racked and clarified.

The clarification

It is carried out by « kieselguhr » filtration. Then our wines are stabilized in contact with the natural cold of our vat room.

Once their solid particles have been removed, our “basic” wines, now limpid, are called “clear wines”, that are ready to be blended.

Blending

It is by blending wines with different aromatic and organoleptic qualities that we proceed with the assemblage, the art of creating a wine that is superior to the sum of the former.

What underlies this approach has always been for us the search for a particular harmony between the notes, so that no one dominates and one feels a sense of balance in the mouth.

Learn more

Blending

The blending of our wines from our 3 grape varieties allows us to create contrasts while complementing each other thanks to the body of the Pinot Noir, the fruitiness of the Meunier and the finesse of the Chardonnay.

From one year to the next, the climatic conditions of the Champagne terroir varies. The quality of the grapes, and therefore of the musts and the wines made from them, depends on various factors such as frost, sunshine, rainfall, etc. The blending of our wines from different years tends to balance the resulting diverse qualities.

Our plots of land, all located in Rilly-la-Montagne, allows us to reveal the specific qualities of this cru: our wines from this unique terroir guarantee the constancy of its aromas.

Moreover, the technique of massal selection applied in our vineyard and handed down by our ancestors allows us to maintain the continuity of flavours in our wines, thanks to the varietal diversity of our vines (70 year old vines) which gives them a particular aromatic typicity.

Each year in January, we have a real palette to imagine how we can create the best complementary mix between our wine from the previous harvest and our reserve wines, always with a desire to maintain the specific style and durability of our champagne (a vinous style that’s balanced in the mouth).

However, every so often, a remarkable year can be noted from a vintage if we judge that the flavours and balance of the wine from that year are exceptional enough, so that we do not have to resort to reserve wines.

Finally, the art of blending is a prelude to the other stages of the Champagne method – drawing, sparkling, ageing on deposit, riddling, disgorging, and dosing – which will amplify further the harmony created by the blending.

Bottling & "prise de mousse"

Once harmony has been found, the wine is bottled with its tirage liqueur and then lowered into cellars at 12 ° C where fermentation in the bottle known as “prize de mousse” will take place. It’s about capturing the excitement!

Learn more

Bottling and « prise de mousse »

The tirage consists of the “bottling” of our wine which will undergo the fermentation in the bottle, intended to make the wine sparkling, hence the name “prise de mousse”.

To carry out this fermentation, we add a liqueur to the wine called “tirage”, made up of cane sugar, leaven, and a stirring adjuvant.

The leaven is a culture of selected yeasts, previously acclimatised in the middle of the wine. We choose the yeasts that best suit our wines to create the greatest complexity when they come into contact with the wine during ageing.

In accordance with the regulations that prohibit decanting (from half-bottle to jeroboam), the wine is sold in the bottle in which it was made. The Champagne bottle, which can only be made of glass, meets specific specifications because it must, among other things, resist very high pressure and numerous manipulations.

After filling, the bottles are hermetically sealed by a polyethylene stopper called a “bidule” with a crown cap, then taken down to the cellars at 12°C where they are placed “on slats”, i.e. lying down and stacked, row on row, in pallet boxes.

This is followed by the “prise de mousse”, which lasts 6 to 8 weeks, during which the yeasts consume the sugar and release into the wine, in addition to alcohol and carbon dioxide, esters and higher alcohols. Which all contributes to the sensory characteristics of the wine.

Ageeing on lees

The lees, consisting essentially of yeast, which gradually disappear once the sugars have been consumed, will form the deposit.

They will remain in contact with the wine for many years, creating interactions with it which are at the origin of the development

of the complexity of its aromas. In order for our wines to reach their full maturity in contact with the lees, we let them age

between 4 and 9 years.

Load more

Ageeing on lees

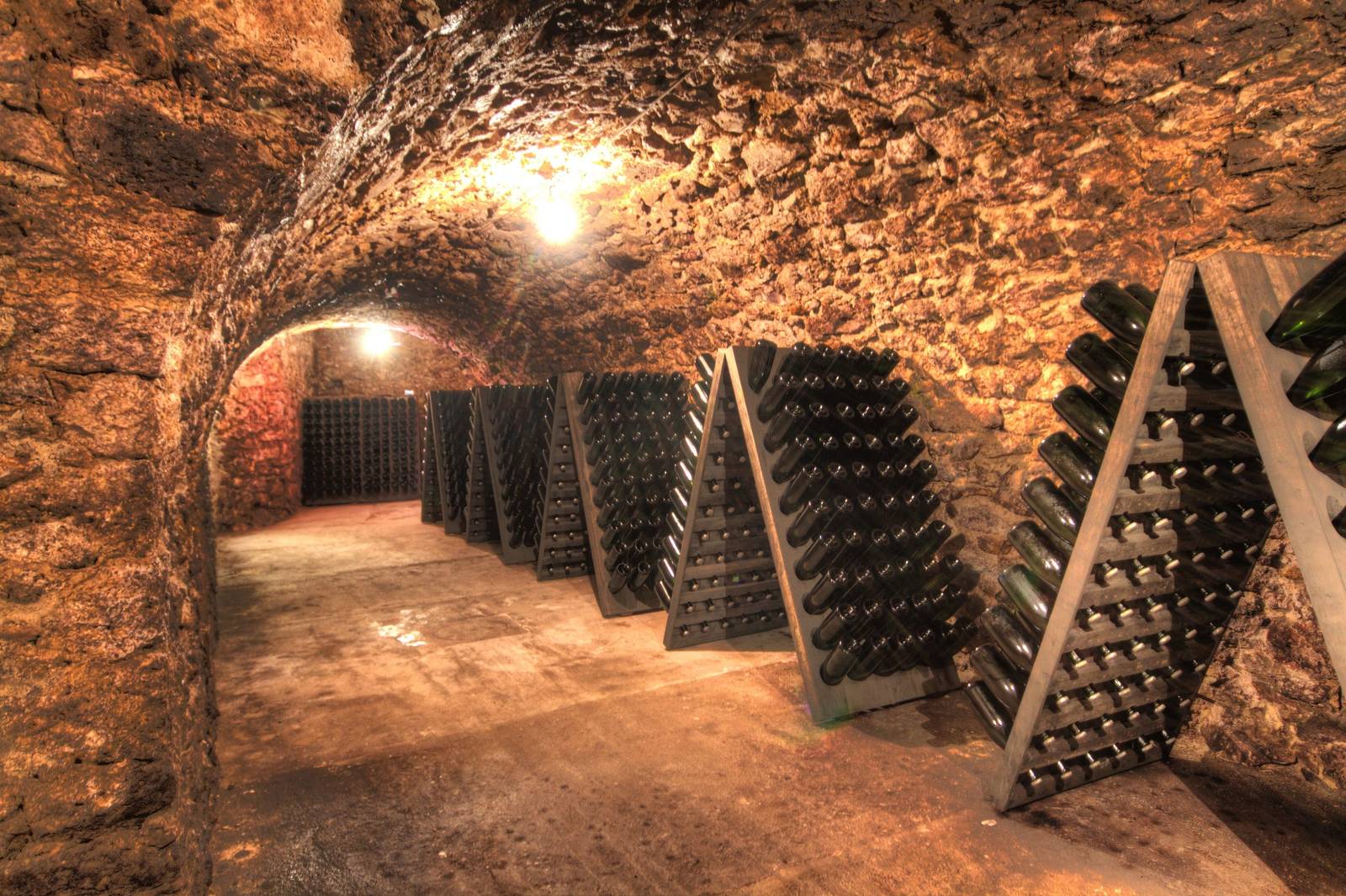

Shielded from the light, the bottles remain in our cellars for a long period of maturation. The cellars play a major role in this important stage of winemaking thanks to their relatively constant temperature, of around 12°C.

The lees are essentially made up of yeasts which have multiplied in the bottle and form a deposit. Once the foam has formed, the yeasts gradually die out and become autolysed: their cellular content degrades and releases molecules that interact with those of the wine and undergo slow transformations.

In parallel with autolysis, a minute amount of oxygen enters the bottle through the draft stopper, while a small amount of carbon dioxide escapes. The tightness is therefore not absolute. The choice of corking is a very determining parameter depending on the speed of evolution one is looking to achieve.

Maturation on lees therefore combines two phenomena:

- yeast autolysis

- the slow oxidation from clogging.

In Champagne, they combine ideally given the fine and delicate structure of the wines. This crucial stage in the winemaking process thus brings specific aromas to Champagne wines and allows the progressive development of the aromas of maturity and fullness, known as tertiary aromas.

By law, at least 15 months must elapse between bottling and dispatch, 12 of which must be on the lees. This period is extended to 3 years for vintages.

This legal period, which is already significant compared to other sparkling wines*, is longer for us: depending on our cuvées, we estimate between 4 and 9 years of ageing necessary for our wines to reach their full maturity on contact with the lees.

*European regulations only impose a minimum period of 90 days for sparkling wines. Champagne wines are the only ones to have such a long maturation period.

After such a long period of ageing in the calm and mysterious underground galleries, our bottles are regularly stirred by hand to collect the deposit in their neck.

Manual disgorging

Disgorging consists of eliminating the deposit that riddling has concentrated in the neck of the bottle using ancestral know-how passed down from generation to generation.

Learn more

Manual disgorging

Disgorging consists of removing the deposit that the riddling has concentrated in the neck of the bottle.

It is a crucial moment in the life of the wine, after the time of maturation on the lees, when no external event disturbs the wine.

To do this, the neck of the bottle is immersed in a glycol solution at around -27°C, forming an ice cube in the neck which traps the sediment in the bottle.

The bottle is held upside down and is opened by straightening it quickly so that the pressure expels the deposit without letting too much wine escape.

At the opening, the internal pressure allows the ice cube to be ejected with a minimum loss of wine and pressure.

During this operation, a small quantity of oxygen enters the bottle, it contributes, together with the dosage liqueur added at this stage, to the evolution of the aromatic characteristics of the wine.

Dosage

The dosage is the last touch brought to the wine before the final corking of the bottle.

It corresponds to the addition of a small quantity of liqueur.

Learn more

Le dosage

The dosage liqueur, also known as “expedition liqueur”, is composed of cane sugar dissolved in wine.

The quantity of liqueur used for the dosage depends on the type of wine to be obtained:

- « Doux » :more than 50 grams of sugar per litre

- « Demi-sec » :between 32 and 50 grams of sugar per litre

- « Sec » : between 17 and 32 grams of sugar per litre

- « Extra dry » : between 12 and 17 grams of sugar per litre

- « Brut » : less than 12 grams of sugar per litre

- « Extra brut » : between 0 and 6 grams of sugar per litre

When it contains less than 3 grams and if no sugar has been added to the wine, the words “brut nature”, “non-dosé” or “dosage zéro” may be used.

The role of the dosage in the sensory development of the wine may be small or large.

We wish to preserve the integrity of the personality of our wine with a liqueur that is as neutral as possible. The wine lost during disgorging is replaced by a little of the same wine combined with cane sugar.

Whilst it ensures maximum tightness, the cork does not completely prevent gas exchanges. As with the draught stopper, a little oxygen penetrates over time and the wine continues to evolve.

Corking & Labelling

Immediately after dosage, the wine is corked to start a new stage of its ageing. The bottles are then vigorously shaken (wrist stirring) to ensure the homogeneity of the wine and the liqueur, and their controlled limpidity (mirage).

Then they return to the cellar for another 6 months before being marketed.

The last step is to carefully dress the bottles with their labels and place them in their carton to protect them during the long journey to your table!

Learn more

The stoppers currently in use are made up of a part composed of agglomerated cork granules on which two cork washers are glued (the one in contact with the wine is called a “mirror”).

The cork stopper must obligatorily be marked with the name of the Champagne designation and, if necessary, the year of the vintage.

Once inserted by compression into the neck of the bottle, the cork is covered with an over-corking plate (capsule), all of which is secured by a muzzle to hold the stopper in place.

Whilst it ensures maximum tightness, the cork does not completely prevent gas exchange.

As with draft corking, a little oxygen penetrates over time and the wine continues to evolve.